When Australian Bell came to us looking for a way to design a perfectly in tune, as cast, European Bell, we knew we had a challenge on our hands. Bell design has traditionally been a long process of trial and error – more a black art than a science. This gets very expensive when the bell weighs hundreds of kilograms.

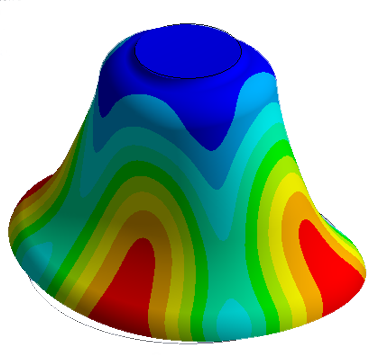

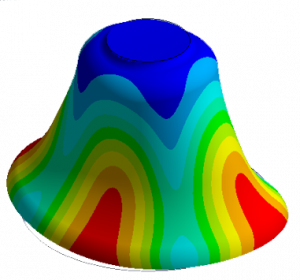

A great sounding bell not only has the correct fundamental frequency to hit the note required but also has the higher natural frequencies, or harmonics, as set multiples of the fundamental frequency. We used our ANSYS FEA software to examine the natural frequencies of bell shapes and devised a strategy for altering the shape of the bell to vary each frequency almost independently. After some iteration we achieved just what our client was looking for.

The first bell has just been cast by Australian Bell at Billmans Foundry in Castlemaine Victoria and has since been tested. A 3D printed pattern was made, ensuring the shape of the casting was as accurate as possible. The bell is about to be installed in Moonta, South Australia.

- 3D printed pattern

- Casting in progress

- The fundamental frequency mode shape

- The final bell